Sustainable Engine Cooling System (SECS)

Scania Group, Södertälje, Sweden (2016)

Role:

Lead Mechanical Engineer

Tools/Technologies used:

SolidWorks, ANSYS Thermal, LabVIEW

Duration:

14 months

Team size:

20 members

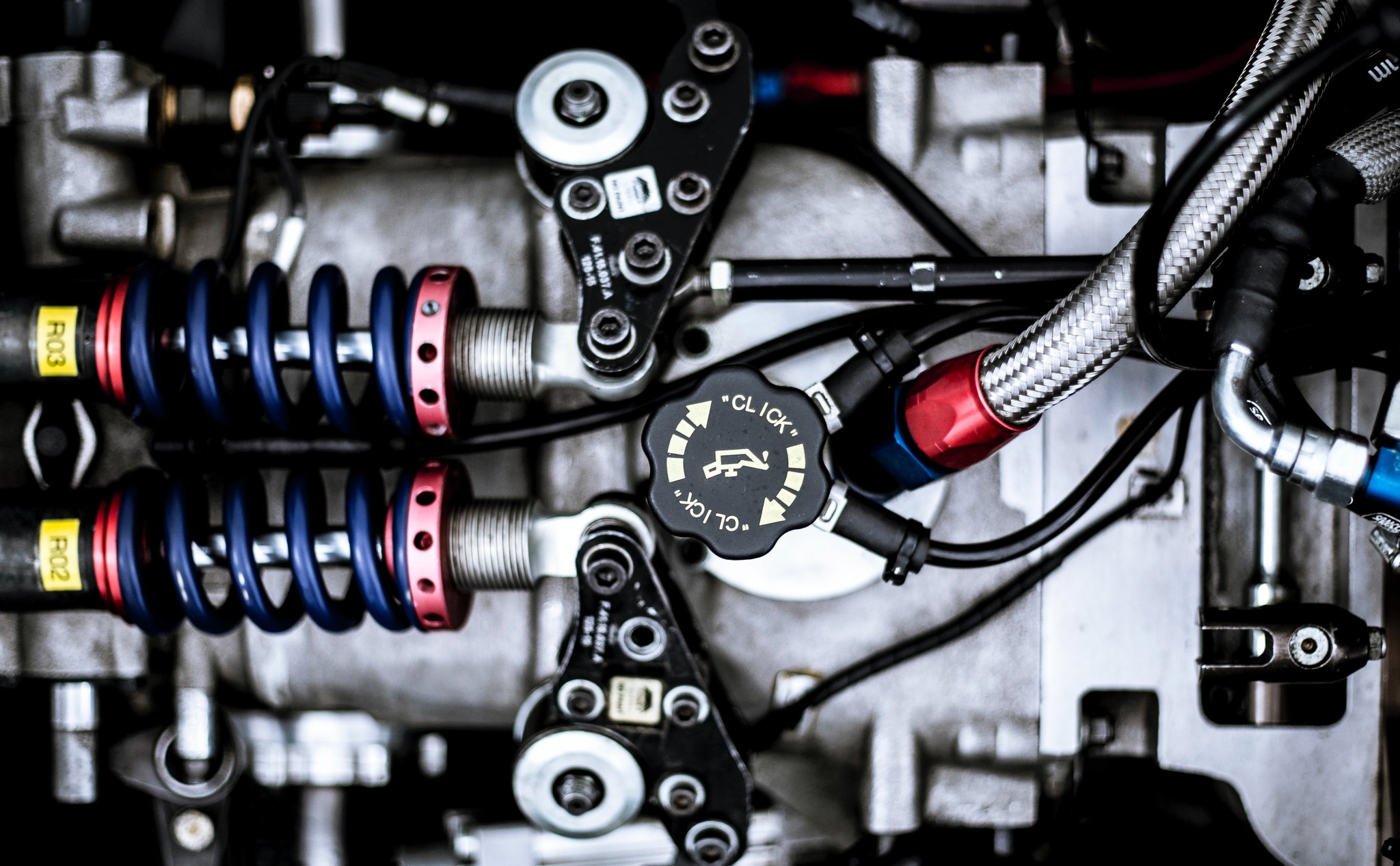

Project Objective

The aim of the SECS project was to develop a cutting-edge engine cooling system for Scania trucks that not only maintains optimal engine temperatures but does so using sustainable practices, reducing overall emissions and increasing fuel efficiency.

Process & Challenges

To achieve this, the project began with thorough research into sustainable materials and coolants. Prototypes were designed to test different configurations, with a strong emphasis on minimizing energy consumption and waste. One major challenge was ensuring that the sustainable elements incorporated did not compromise the engine's performance. Additionally, scaling the cooling system to fit different truck models without a drop in efficiency presented its own set of challenges.

Outcomes & Impact

The culmination of the SECS project was a patented cooling system design which reduced engine heat-up times by 30% and lowered CO2 emissions by 5%. This innovative approach also resulted in improved fuel economy for Scania trucks. Post its success, the SECS design became a standard feature in the new generation of Scania trucks.

Conclusion & Learnings

The SECS project highlighted the crucial balance between sustainability and performance in modern engineering projects. It taught the team the value of iterative design and the importance of cross-functional collaboration, especially when working towards an eco-friendly solution in a performance-centric industry.